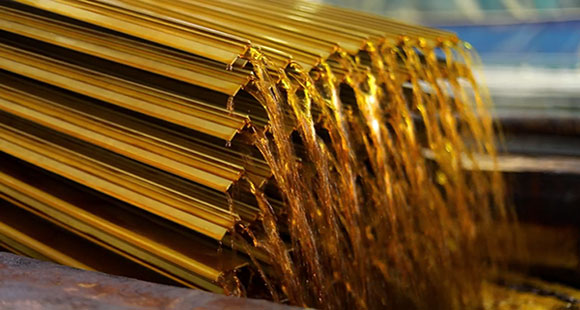

Anodaizing Unit

Anodizing is called for chemically building a thin layer of oxide on aluminum parts, which causes increasing hardness, corrosion resistance, beautiful appearance and changes in some of its physical properties.

The overall anodizing mechanism is performed by plunging aluminum into an acid solution and transferring electrical current through the environment. The cathode connects to the anodized tank. Aluminum acts as an anode, so oxygen ions are released from the electrolyte to be combined with anodized aluminum. In this case, a thin layer of aluminum oxide is built on the aluminum surface. Unlike most other products, Anodized naturally maintains its contexture and metallic beauty. The anodized coating has hardness and durability, and will never be desquamated and also destroyed under normal conditions. Aluminum is anodized for its beautiful appearance, corrosion resistance, hardness and abrasion resistance, elegance in industrial applications, and for a numerous specialized reasons.